How Soyabean Protein is Extracted?

- Indrajeet Paul

- Jan 23

- 5 min read

Updated: Jan 24

The COVID-19 period led many to rethink their food choices. Health, immunity, and nutrition became part of everyday conversation. In a country with a large vegetarian population, this also meant questioning long-standing dependence on dairy and other animal-derived products.

Between 2021 and 2022, dietary preferences began to shift. Around 24% Indians identified as vegetarian, while close to 9% followed a vegan diet. Many others started reducing dairy and meat intake without eliminating them.

This raised a simple question: How can protein requirements traditionally met through milk and whey be replaced? Answer: Soya Protein.

It is plant-based, lactose-free, and widely used across food categories. The Indian soya protein market is expected to reach USD 761.9 million by 2030, growing at a CAGR of 5.91%.

As demand grows, understanding next-gen soy protein extraction becomes essential for companies and consumers. Knowing how soya protein is extracted helps explain its quality, safety, and everyday use.

Soya Protein Extraction: A Step-by-Step Process

At Prowise India, soya protein extraction follows a structured, industry-grade process designed to ensure quality, consistency, and scalability. This modern soy processing method focuses on efficiency while preserving protein integrity.

Breakdown of the Soya Protein Extraction

The following is a clear breakdown of the soy protein extraction process, from raw material to finished protein ingredient:

Whole Soyabeans: Sourcing and Quality Control

Soya protein extraction begins with the selection of whole soyabeans. Protein yield and functionality depend heavily on the quality of the raw material. Beans are evaluated for maturity, protein percentage, moisture content, and microbial safety.

We source non-GMO soyabeans to meet regulatory compliance, export-readiness, and clean-label requirements. Farming practices and post-harvest storage are monitored to avoid fungal growth or protein degradation. Only beans that meet food-grade standards move into processing.

This step ensures consistency across batches and serves as the foundation for whole soybean extraction in our state-of-the-art manufacturing facility.

Cleaning, Dehulling, and Flaking

Once sourced, soyabeans are cleaned to remove foreign matter such as dust, stones, and metal particles. This protects downstream equipment and ensures food safety.

The hull is then removed. Soya hulls contain fiber but very little protein, so dehulling improves protein concentration. The beans are cracked and passed through flaking rollers. Flaking increases surface area, which allows water and processing agents to interact more effectively with the protein during extraction.

This stage improves extraction efficiency without altering protein structure.

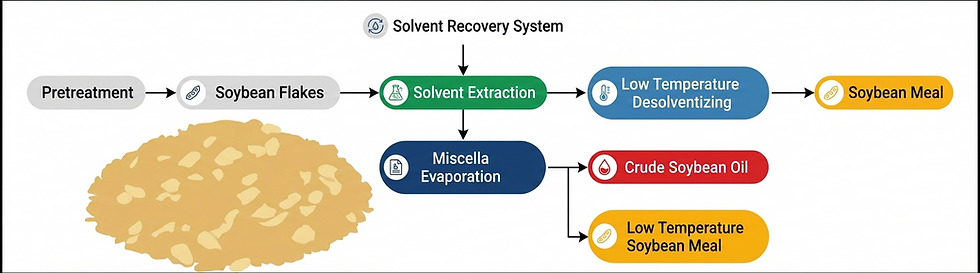

Defatting and Preparation of Soya Flour

Flaked soyabeans still contain oil, which must be removed before protein extraction. Oil interferes with protein solubility and separation.

Defatting is carried out using mechanical pressing or food-grade solvent extraction. The result is defatted soya flour with a higher relative protein content. Particle size is controlled to ensure uniform hydration and consistent processing in later stages.

This step ensures the soya protein extraction process proceeds smoothly and efficiently.

Aqueous Extraction and pH Control

In this stage, defatted soya flour is mixed with water to create a smooth slurry. This is known as aqueous extraction, simply meaning protein extraction using water as the medium.

The pH of the mixture is then adjusted to alkaline levels, usually between 8 and 10. pH refers to how acidic or alkaline a solution is. Soya proteins respond to changes in pH. Under alkaline conditions, the protein becomes soluble, allowing it to dissolve in water, while most non-protein components remain insoluble.

Maintaining the correct pH and temperature is critical. It ensures the protein dissolves efficiently without losing its nutritional value or functional properties. This water-based method forms the core of next-gen soy protein extraction and is widely used in well-equipped soya processing plants, like ours, for consistent and scalable results.

Solid-Liquid Separation

After aqueous extraction, the mixture contains dissolved soya protein along with insoluble components such as fiber and carbohydrates. These solids need to be removed to obtain a clean protein-rich liquid.

Solid–liquid separation is carried out using centrifugation or filtration. Centrifugation uses rotational force to separate heavier solid particles from the liquid. Filtration may be used alongside this to clarify the extract further.

This step ensures that only soluble protein moves forward in the process. Efficient separation improves protein purity, increases yield, and prepares the liquid for further refinement. It is a critical stage as poor separation can affect both the quality and consistency of the final product.

Protein Precipitation, Washing, and Neutralization

Once the protein-rich liquid is separated, the pH is adjusted again, this time lowered to around 4.5. This point is known as the isoelectric point, at which soya protein becomes insoluble and separates from the liquid.

As the protein precipitates, it forms a concentrated mass that can be collected using centrifugation. The protein is then washed with water to remove residual acids, salts, and non-protein components. This improves purity and reduces unwanted taste.

After washing, the protein is neutralized to bring the pH back to a stable level suitable for food applications. Neutralization helps preserve protein functionality, improves shelf stability, and ensures consistent performance across different food formulations.

This stage determines the final quality of soya protein.

Drying and Final Protein Forms

After neutralization, the soya protein remains in a wet state and needs to be stabilized for storage and use. This is done through drying, most commonly using spray drying. Spray drying removes moisture quickly and evenly, converting the protein into a fine, free-flowing powder.

Drying improves shelf life, handling, and ease of application across food systems. Particle size and moisture levels are controlled to ensure consistent performance.

At this stage, the protein is classified based on its purity. Soy protein concentrate retains some soluble carbohydrates and has a moderate protein content. Soy protein isolate undergoes further purification and contains over 90% protein.

These final forms are widely used in bakery, snacks, beverages, nutraceuticals, and everyday food products, completing the modern soya protein extraction process.

Trusted and Functional Soya Protein at Prowise India

At Prowise India, soya protein extraction follows a systematic, step-by-step process designed for consistency, safety, and performance. We specialize in soy protein isolate, supplying high-quality protein ingredients to manufacturing companies across the FMCG and nutraceutical sectors.

As the only soya protein manufacturer in India, Prowise India, we ensure every batch is produced under strict quality checks and complies with ISO and FSSAI standards. This ensures traceability, food safety, and dependable output at scale. For food manufacturers and partners seeking long-term reliability, technical expertise, and consistent supply, we offer a proven processing framework backed by industry compliance standards.

FAQs

Does soya protein extraction reduce its nutritional value?

Ans: No. When carried out using modern, regulated processes, soya protein extraction preserves the core nutritional profile. Protein quality, amino acid composition, and digestibility remain intact. Controlled pH, temperature, and drying methods ensure nutrients are not damaged during processing.

What makes soya protein isolate different from whole soya flour?

Ans: Soya protein isolate undergoes further purification to remove fats and carbohydrates, resulting in a protein content of over 90%. This makes it more concentrated, neutral in taste, and better suited to precise food formulations than whole soya flour.

Is soya protein safe for long-term consumption?

Ans: Yes. Food-grade soya protein produced under ISO and FSSAI-compliant conditions is safe for regular consumption. It has been widely used across global food systems for decades in everyday products.

Why is aqueous extraction preferred in modern soya processing?

Ans: Aqueous extraction uses water as the primary medium, allowing precise control over protein separation. It improves purity, scalability, and consistency while maintaining protein functionality, making it ideal for large-scale food manufacturing.

Comments